Water Transfer Printing: Draping Objects in 'Magic Skins', Personalized Customization Leads New Trend in Manufacturing

In a consumer era driven by personalization and differentiation, a surface decoration technology known as Water Transfer Printing (WTP) is quietly revolutionizing the "aesthetics economy" of manufacturing. With its unique process and exceptional adaptability, WTP has rapidly expanded beyond niche applications like automotive customization and sports equipment to penetrate consumer electronics, home decor, and even the fashion industry, becoming a new engine for product value addition.

Technical Principle: When Water Becomes the "Paintbrush"

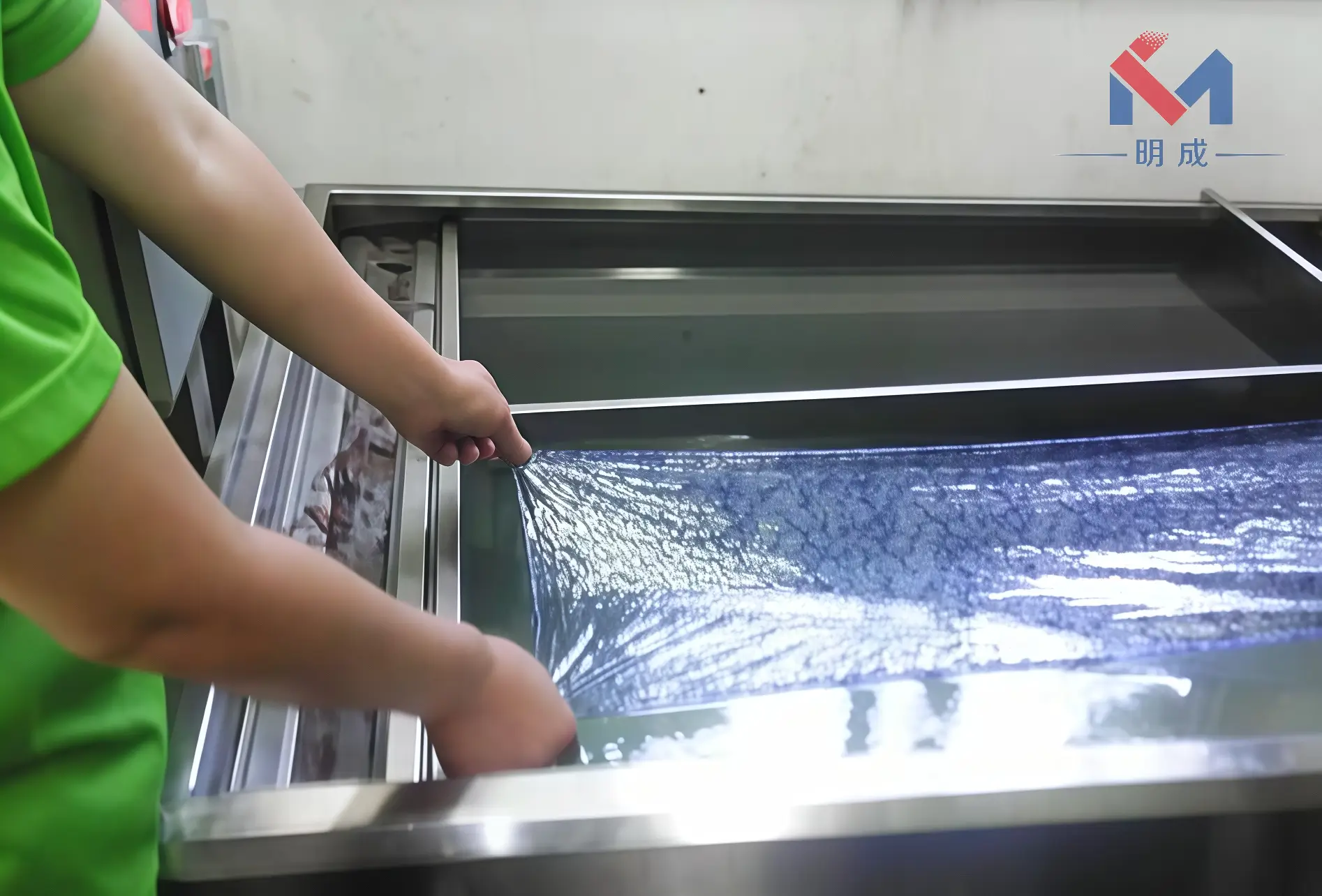

Water Transfer Printing, also called Hydrographic Printing or Hydro Dipping, relies on the surface tension of water and the action of activators to transfer intricate, full-color patterns from eco-friendly films onto product surfaces. During the process, the printed film is floated on a water tank, sprayed with an activator to dissolve the ink layer, and then the object is immersed. The water flow naturally conforms to the contours, enabling seamless 360-degree coverage. Whether for complex irregular components or tiny electronic parts, high-definition patterns can be precisely applied.

Exploding Applications: From "Industrial Parts" to "Lifestyle Aesthetics"

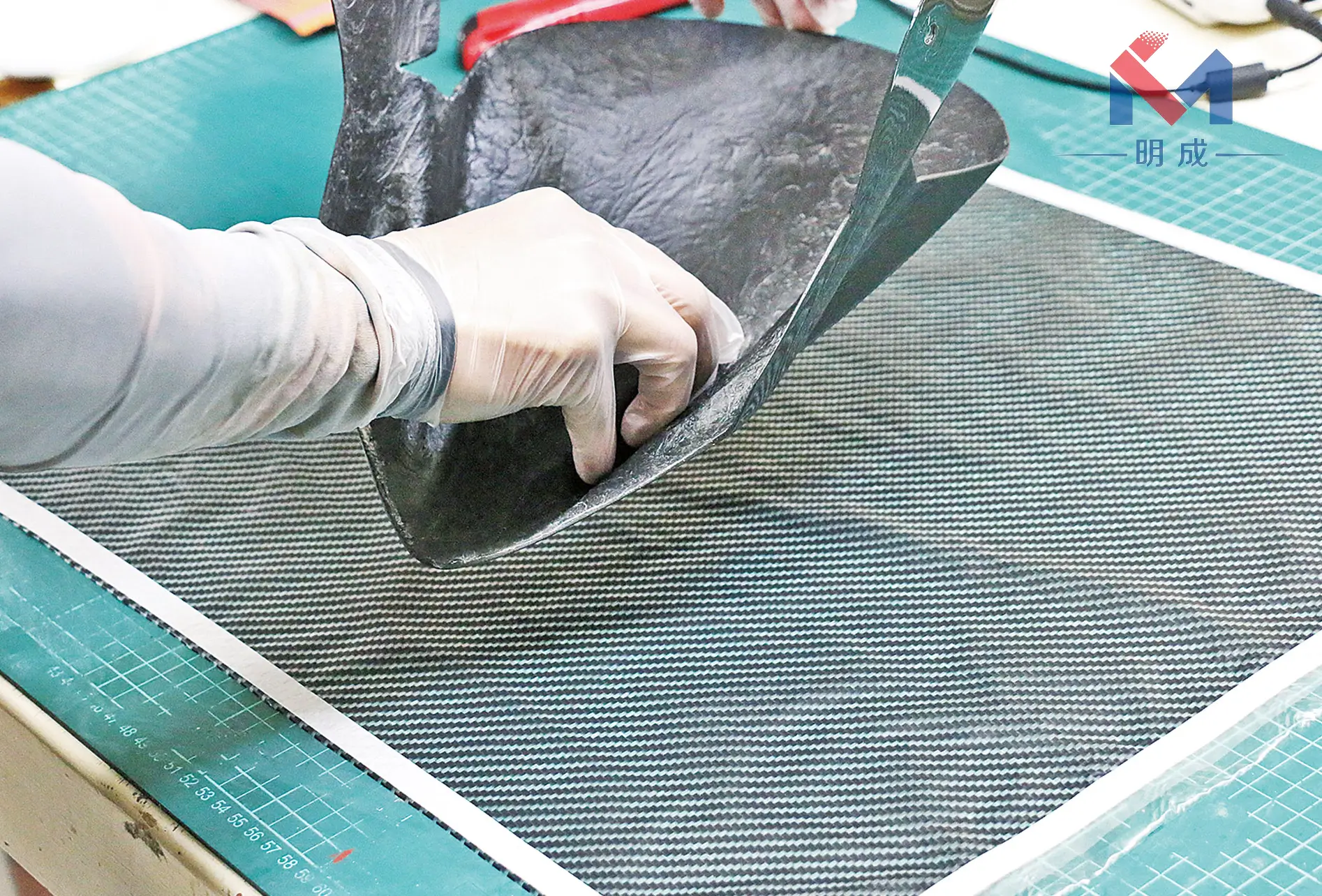

- Automotive Industry: Carbon fiber textures, wood grains, and camouflage coatings on steering wheels, interior panels, and engine covers significantly expand vehicle customization options.

- Consumer Electronics (3C): Phone cases, headphones, and game controllers featuring marble patterns, gradient starry skies, and other limited-edition designs via WTP become "social currency" for young consumers.

- Home Furnishings & Building Materials: Stone and wood imitation effects on baseboards, door/window profiles, and sanitary ware offer high realism at low cost.

- Sports Equipment: Bicycle frames, helmets, and skateboards gain brand identity through lightweight, customized graphics.

Winning with Eco-Friendliness and Efficiency: Accelerated Tech Evolution

Amid tightening environmental regulations, WTP technology is upgrading towards greener solutions. The use of water-based inks and biodegradable films significantly reduces VOC emissions. Meanwhile, the introduction of automated dipping equipment and AI visual positioning systems has boosted printing precision to ±0.1mm and increased production efficiency by over 40%. A manager at a Shenzhen materials company stated, "While WTP once relied on artisan experience, intelligent production lines can now process tens of thousands of parts daily. Customization can be achieved at scale."

A Billion-Dollar Market Beckons: Opportunities for SMEs

According to the Global Surface Decoration Market Report, the WTP-related industry is projected to exceed $18 billion USD in 2025. China's domestic supply chain has matured, forming industrial clusters in the Pearl River Delta and Yangtze River Delta regions, encompassing film R&D, ink production, and processing services. A toy factory in Dongguan that transitioned to WTP processing reported: "A single production line can handle cross-category orders for phone cases, blind boxes, and small appliances, achieving 25% higher gross margins than traditional OEM manufacturing."

Expert Insight: "The boom in Water Transfer Printing stems from upgraded consumer demand for the 'visual economy,'" noted Li Ming, Secretary-General of the Light Industry Design Association. "It breaks the limitations of flat printing, giving curved products a sense of 'high-end customization.' In the future, combined with nano-coating technology, its wear resistance and corrosion resistance will further improve, showing immense potential in sectors like new energy vehicles and smart home appliances."

Conclusion: As "aesthetics-driven manufacturing" becomes an industry consensus, Water Transfer Printing, with its triple advantages of flexible production, low-carbon environmental friendliness, and powerful creative potential, is redefining the boundaries of surface treatment. With the deepening integration of Chinese cultural IP, digital art, and physical industries, this "aquatic magic" may well spark a new wave of design revolution.