Solutions for Appearance Defects in Hydrographic Printing Equipment Production

Appearance defects (e.g., blurred patterns, bubbles, scratches, missing prints) during hydrographic printing often relate to equipment parameters, material quality, and operational procedures. Targeted troubleshooting is essential. Below are causes and solutions for common defects:

1. Blurred Patterns & Poor Definition Causes:

- Low-quality film (poor resolution, weak ink adhesion)

- Uneven/over/under spraying of activator causing incomplete/over-dissolution

- Oil/dust on substrate surface affecting transfer

- Water temperature too high (premature dissolution) or low (slow dissolution causing ink diffusion)

Solutions:

- Use Dongguan Caiyide premium films with flat surfaces, clear patterns, and stable ink

- Optimize activator spraying: Maintain 20-30cm nozzle distance, uniform coverage (slightly dissolved without pooling). Adjust concentration per film type (e.g., PET/PP films)

- Enhance substrate pretreatment: Clean with alcohol/specialized agents; apply sandblasting/phosphating for adhesion

- Control water temperature at 25-30℃ (film-specific) without fluctuations

2. Bubbles & Wrinkles Causes:

- Air trapped by vertical substrate immersion

- Residual solvent from unvaporized activator

- Water turbulence causing film wrinkling

- Uneven film stretching on edges/protrusions

Solutions:

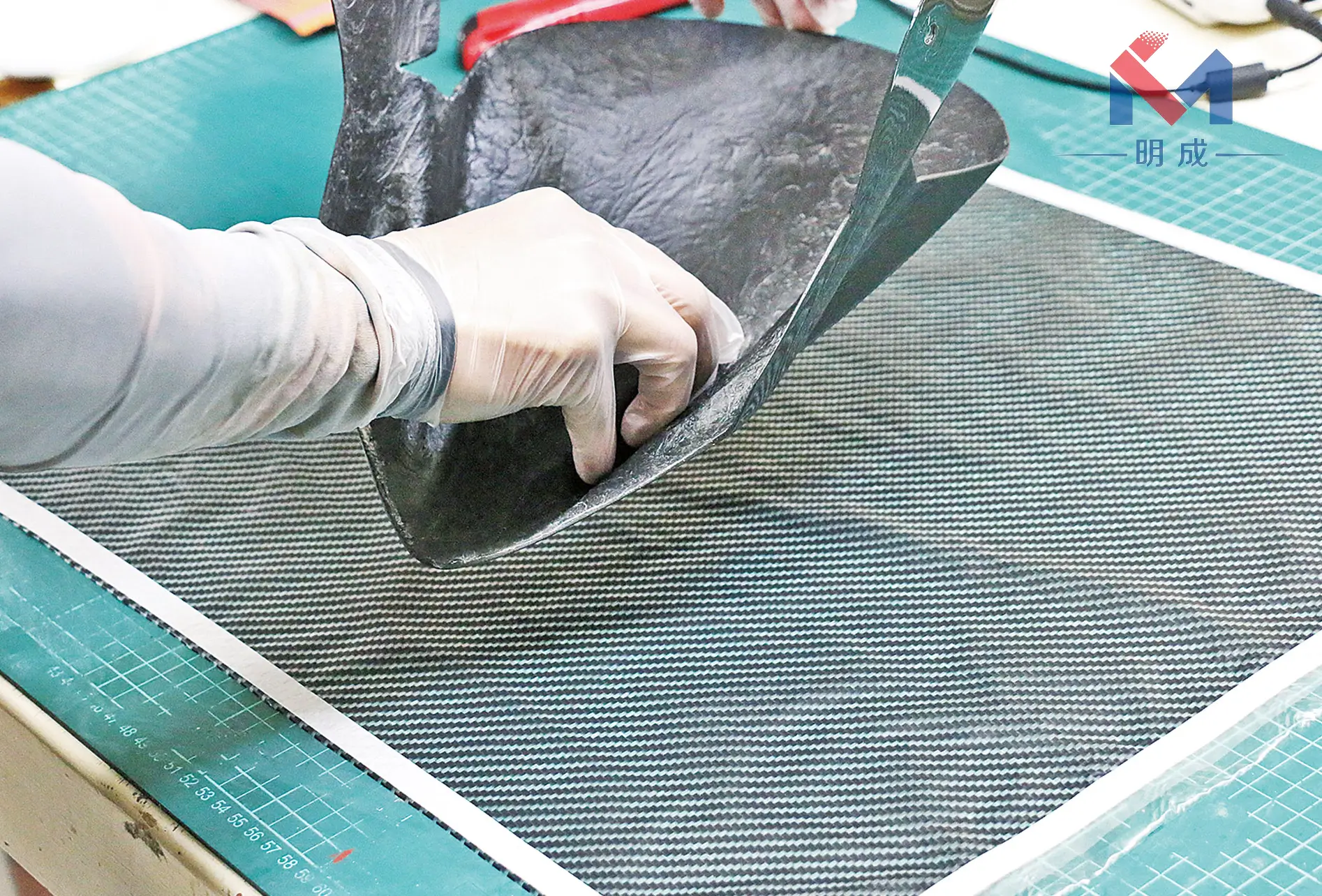

- Immerse substrate at 45° angle; use squeegees for complex contours

- Allow 5-10s activator drying (environment-adjusted) until tacky

- Install baffles for still water; ensure smooth film deployment

- Pre-heat edges (50-60℃) for elasticity; press wrinkles with soft sponges

3. Missing Prints & Pattern Breaks Causes:

- Localized undissolved film (activator skip-spray or film damage)

- Mold release agents/wax hindering adhesion

- Film displacement by water flow

- Incomplete curing causing peeling

Solutions:

- Verify full activator coverage; discard damaged films (Dongguan Caiyide QC recommended)

- Remove contaminants with dedicated cleaners or high-temperature baking (metal: 200℃+)

- Add water tank positioning guides; align film before immersion

- Air-dry 10-15min post-transfer; cure at 60-80℃ for 15-30min

4. Scratches & Contaminants Causes:

- Debris (dust/film fragments) in water tank

- Substrate burrs scratching film

- Dirty post-processing tools

Solutions:

- Replace water daily; filter circulation system; skim surface pre-transfer

- Polish substrates to remove sharp edges

- Wipe with lint-free cloths; install dust screens in ovens

5. Color Deviation & Mottling Causes:

- Chemical reactions between activator and ink

- High water temperature dispersing ink

- Excessive curing temperature degrading ink

Solutions:

- Use Dongguan Caiyide compatible activators (consult suppliers) compatible activators (consult suppliers)

- Strictly control water temperature (heat-sensitive films: ≤28℃)

- Set curing temperature per ink tolerance (typically ≤80℃); ensure oven uniformity (±5℃)

6. Preventive Measures

- Equipment Calibration: Regularly check tank level, conveyor speed, and activator pressure (Dongguan Caiyide standard)

- Material Inspection: Test film/activator samples before batch use

- Operational Training: Standardize immersion angles, spraying techniques, etc.

- Environmental Control: Maintain cleanroom conditions (20-30℃/50-70% RH); install dust-proof systems